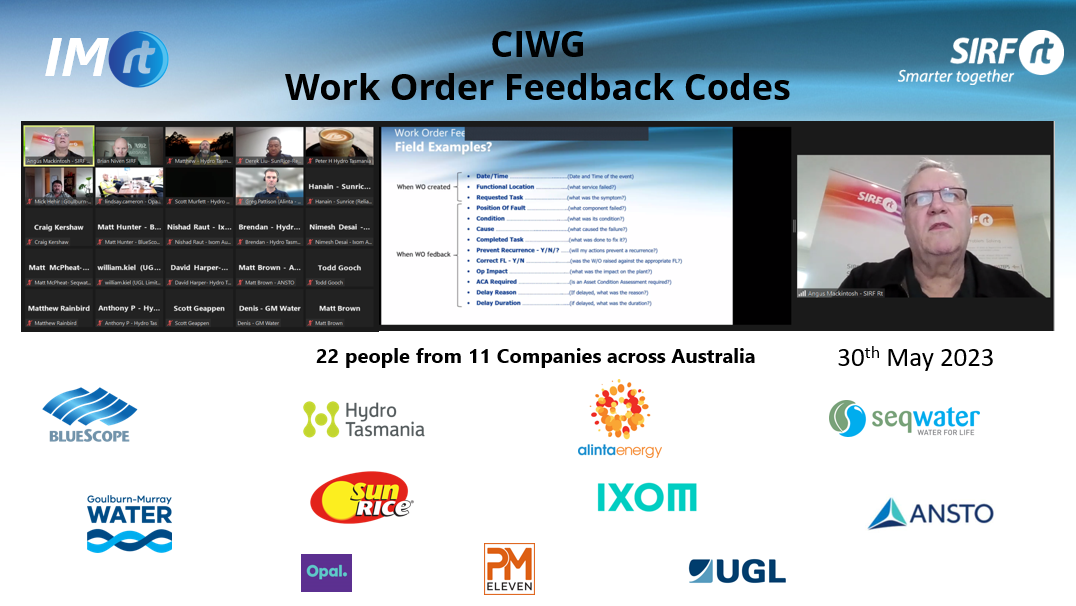

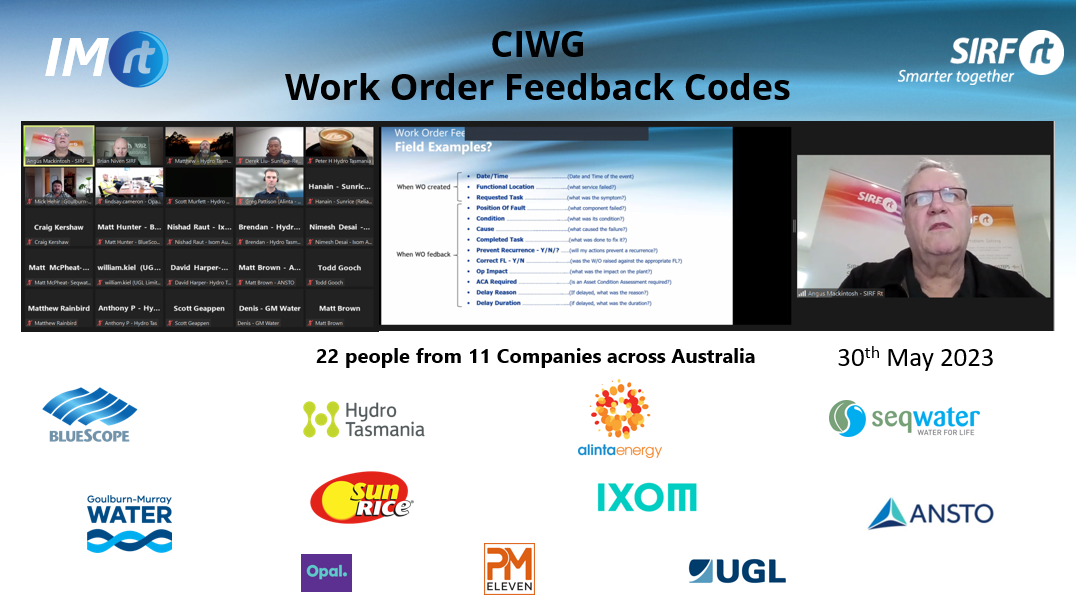

Thank you all who attended the SIRF IMRt CIWG – Work Order Feedback Codes.

Angus Mackintosh from SIRF presented on Work Order Feedback Codes, highlighting Why Feedback Codes, Examples of Feedback Codes, The Story, Reports and Problem Assets.

Our thanks also go to Greg Pattison of Alinta Energy for his presentation on LYB Feedback Codes and Matt McPheat from Seqwater on his presentation on how they use feedback codes in their mobility solution.

There was a lot of discussion and questions and networking via breakout rooms.

We had 22 People from 11 Companies across Australia attend.

People came with the following Aims:

- Understand how others use feedback codes.

- just see what others are doing in this space

- Best practices to record feedback from inspections, and make sure future work gets recorded

- We are implementing a new CMMS system and looking at ways to improve feedback we received on completed WO

- Examples of how to get people on the coal face to enter data

- See if there are better way to capture work history for decision making

- How the feedback is provided for each work order and used in future

- To see how to efficiently utilize feedback codes .

- understanding how other organisation do it

- Hopefully get some consistency across Hydro Tasmania in the way we use work orders

- How to make feedback codes work for our business

- Best way to get the most out of entering history. Make it simple.

- How to provide consistent quick outcomes from work orders10:18:37 From Mick Hehir : Goulburn-Murray Water to Everyone:

- To ensure that my logic on Work Order feedback code structure is sound & as simple as possible for execution teams when closing Work Orders, whilst providing outputs which are straightforward to analyse.

- Better understanding of best practice for work feedback

- Want to understand how other businesses formulate codes as you can have too many and what the process is that drives their process using these codes

With some of the following comments and questions in the session:

- MEX allows to attach report to respective WO or Assets will that be better

- Good Examples for creating work order

- angus did you make all these fields default so teams had to fill these fields in CMMS

- was these feedback codes put with notification or confirmation screen, more asking for easier reporting

- Replying to "angus did you make..."

- when angus implemented this for us we made them mandatory fields so they had to be filled in for breakdown work orders

- Replying to "was these feedback..."

- We have a separate screen in our mobile device that has the completion data on it, includes these failure code fields to allow a single point for feedback for the trades

- There are 13 fields to fill in. Did you get push back from trades about the amount of data entry required?

- Replying to "was these feedback c..."

- is this a third party mobile solution that works with sap or is this inside the WO

- it was a mobile platform specifically for our CMMS, Tech 1 Cis

- the biggest issue we have is our CMMS system does not allow the failure codes to be filtered from the code above, so the trades had long lists to read through that were not related to the other codes or even the trade doing the work, so some of the entries were less than ideal

- Should problem codes be specific to equipment or generic?

- Angus you mentioned that compliance in CMMS was linked to payroll how did that work

- Replying to "Should problem codes..."

- Matt replied, my experience in reporting on work orders is that if your asset hierarchy is structured properly the codes can be more generic, i.e. "Breakdown"-"Motor"-"Corroded Terminals". You know the motor type because the asset structure identifies it. For my part the Failure Mode is the most important part of the feedback as it can inform the predominant environmental issues to be addressed in your PM Task. Cheers.

- I'm new to Maximo, the previous CMMS system I used was Pronto. Pronto has a "Suggested Improvement" field that technicians could nominate to fill out if WO, PM Task etc. could be improved, this was separate to "History Notes" & could be reported on separately (rather than trawling text fields . Does anyone present know if Maximo has this function?

And left with the following take aways:

- Thanks for the session Gents

- Thanks Angus, Greg and Matt

- I have to jump off for a meeting. Thanks for the presentation Angus and Greg

- Examples of people are doing the process. I have some ideas for or future roll out.

- Make it mandatory!! Keep list short.

- the benefits that can be gained by using codes for reporting

- The need to establish work order feedback code triggers for RCA

- Make it simple as possible for the trades to enter the data

- takeaway is simply seen a couple of examples of what others are doing here.

- unlocking the improved functionality for the trending of problematic maintenance areas by using codes consistently

- It was great Angus, that you highlighted the importance of presenting the beneficial outputs from the CMMS work order feedback data to the execution teams so they are encouraged to get & stay on board. Thanks.

- Thanks all